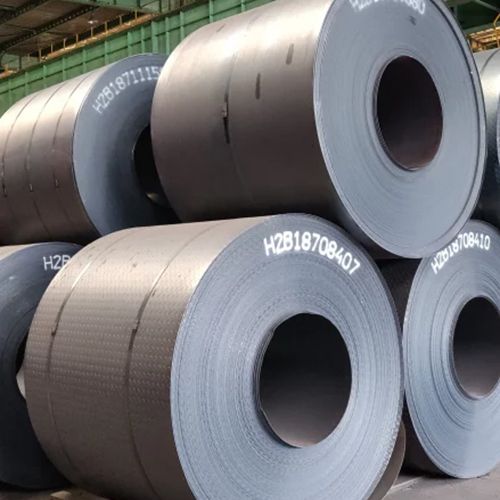

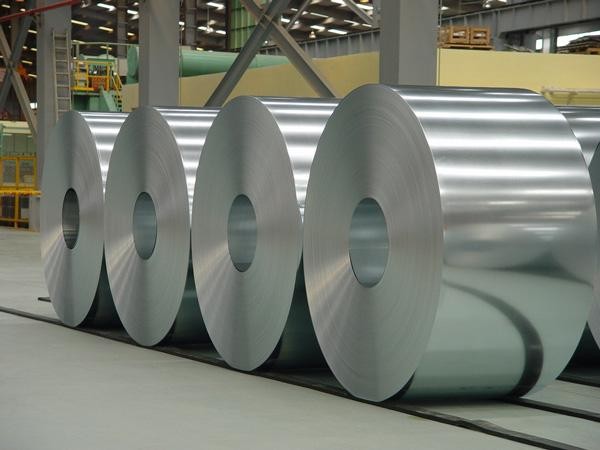

HOT ROLLED COILS

Hot-rolled coil is produced from semi-finished products, which are reduced to certain thicknesses by rolling and annealing and wound into a roll. Hot-rolled steel is used for manufacture of pipes, steel doors and tanks or is further processed into cold-rolled steel. Hot rolled steel bars are used in the welding and construction trades to make railroad tracks and I-beams.

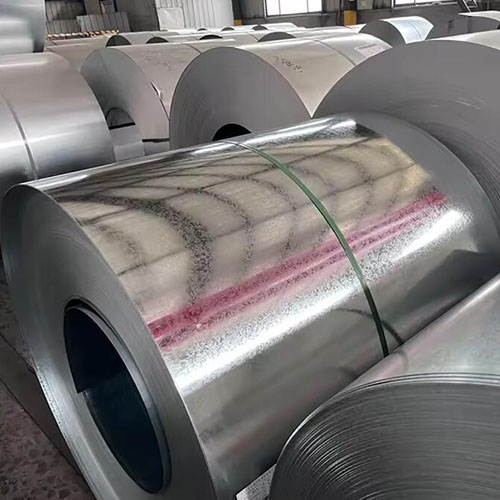

Hot rolled pickled and oiled (HRPO) sheet and coil will scale when in contact with oxygen and water vapour after the forming process. An acid bath removes scale that may form on the surface of hot rolled steel as it cools.

After rinsing, dried oil is applied to the steel’s surface to prevent rust formation, helps to combat corrosion during storage and when in use.

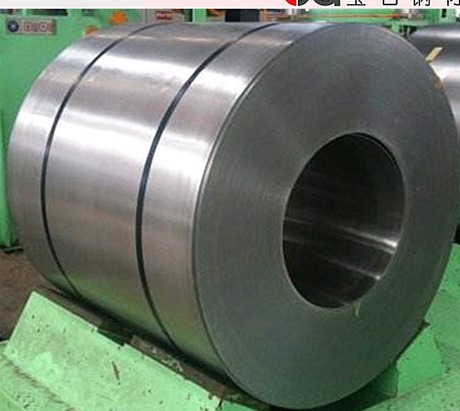

Hot rolled pickled & dry steel products will scale when in contact with oxygen and water vapour after the forming process. An acid bath removes scale and surface oxides that usually form on the surface of hot rolled steel as it cools. After pickling and rinsing, hot rolled pickled are not oiled these dry steel is stored in our climate-controlled warehouse.

Pricing Details

Pricing Details

Product Specifications

Product Specifications

Content library

Content library

Know more about us

Know more about us

Pricing Details

Pricing Details

Our wide range of products and services

Our wide range of products and services