PE (Polyethylene) Layers in Jindal MLC Pipes provides all the advantages of plastic pipes such as, Corrosion resistance, scale resistant, chemically inert, smooth surface for better flow properties, toxic free & rust free.

The Adhesive Layers in Jindal MLC Pipes plays an important role as it perfectly bond the metal and plastic, absorbs eventual shifting movements between the plastic and the metal, likely to occur in opposite directions and gives the Composite pipe the advantages of a single component pipe.

The Aluminium Layer in Jindal MLC Pipes play an important role In addition to all the inherent advantages of plastic pipes the inclusion of the metallic pipe gives Composite pipe the qualities of metal, such as It act as a permeation barrier against entry of contaminants, Limits oxygen permeability to virtually zero, Provide absolute tightness, mechanical resistance to deformation, Dilation within reasonable limits, Increases malleability so bendable and Low heat expansion

Advantages in Detail Any one who grew up with old fashioned plumbing will appreciate the advantage of the Jindal MLC Pipes system. Jindal MLC Pipes flow rate is superior to other systems. So the water pressure is even. It’s virtually maintenance free because it doesn’t rust or corrode. And it’s quiet and reduces noisy water hammer.

Excellent Corrosion Resistance:

Jindal’s plastic layers resist deterioration in aggressive water and hot soil environments. Bury Jindal MLC pipes directly in the ground or encase it in concrete without additional protection. It provides you with a longer service life compared to traditional metallic water service tubing that are susceptible to corrosion and pitting.

Permeation Barrier:

Jindal MLC provides an increased level of protection against contamination of your potable water supply. Unlike plastic water service tubes Jindal’s aluminum core provides a 100% permeation barrier against ground source contaminants like fertilizer, pesticides or chemical spillage. And Jindal’s outer layer prevents deterioration of pipe so your potable water supply is uninterrupted.

Clean and Safe:

Entire PE-AL-PE plumbing system is designed to provide with the cleanest drinking water possible. PE-AL-PE’s clean, non-corroding plastic interior is resistant to deterioration in aggressive water conditions. You need not worry about odor, Color or taste problems arising because of the plumbing pipes in home.As aluminum act as a permeation barrier, the buried Jindal MLC pipes will not be permeated by ground source contaminants.

High Chemical Resistance:

Jindal MLC pipes, due to inner and outer PE layers, are totally inert to most of the chemicals. In addition to all the chemicals to which PE pipes are totally inert resistant, Jindal MLC Pipes offer better chemical resistance than PE pipes for the chemicals such as fuel oils, where the PE pipes fail because of swelling. The chemicals are broadly classified as follows, Jindal MLC Pipes is totally resistant to following chemicals at temperature up to 600 C, Acids, Alcohol, Aldehyde, Ethylene Glycol, Bleach, corrosion inhibitors, Detergents, Foodstuff, Petrol, diesel, fuel oils, Vegetable & mineral oils.

Lower Conductivity:

A Jindal MLC pipe is the bad conductor of heat. Thermal conductivity is 0.45 watt/ [m deg k.]. Because of this the insulation requirement is less compared to GI pipes.

Strength Remains Same After Bending:

The minimum bending radius of Jindal multi layer composite Pipes can be up to 5 times the Outside Diameter. The tensile and compressive stresses developed on outermost and innermost layer of the pipe cross section, respectively, are well within the allowable limits when the bending radius is more than or equal to 5 times of OD of pipe. Hence the pipes bent within this limit are safely used without any reduction in basic strength of pipe.

Cost Efficiency:

The unique characteristics of PE-AL-PE pipes combining long troubles free service life, Safety, weight saving and reduction in diameter required, readily explains the success of PE-AL-PE small diameter piping in the world.In addition, the ease in installation results in improved cost effectiveness of PE-AL-PE compared with other metallic system.

Light Weight and Strong:

Jindal MLC Pipes convenient lightweight long coils make water service line installation simple. And yet Jindal has high pressure ratings and elevated temperature ratings as well. Rated for 15 bars at 23 C.

Quiet Flow:

Noise often associated with water hammer and that banging in pipes behind the wall. PE-AL-PE offers the strength of metal pipes without all the noise. PE-AL-PE’s unique composite construction reduces water hammer pressure and the plastic layers reduce noise. With PE-AL-PE plumbing systems you will have no more shaking or rattling of metal pipes. It all adds up to a quieter home.

Higher Flow Rates:

With a Hazen Williams flow coefficient of c= 150, and large inside diameters, Jindal MLC Pipes provides superior long term flow. Jindal MLC Pipes will not permit build up of calcium or other minerals- unlike metallic pipes; Jindal MLC Pipes flow rate is constant over time.

Support Spacing and Overhang:

With better structural strength due to aluminum layer, as compared to PE pipes Jindal MLC Pipes provides more versatility for in plant piping. Overhang of 1.5 meters can be safely provided for most of the chemicals with specific gravity being equal or lesser than 1. As thumb rule, this distance can be altered in the ratio of the specific gravity of the fluid.

Better Performance at Elevated Temperature:

The reduction in basic strength with the rise in temperature is less as compared to other plastic pipes. Hence, Jindal piping system gives superior service at elevated temperatures up to 80 deg C. as compared to other conventional plastic pipes.

Easy Detection:

Concealed Jindal PE-AL-PE Multi layer composite can be easily detected using metal detectors.

Low Expansion and Contraction:

Jindal MLC Pipes unique composite design makes handle install and behave like a metallic pipe. Its aluminum core controls expansion and contraction, which is similar to coppers. Jindal MLC Pipes rate of linear expansion is 1.3* 10-5 in. /in. /F. As an example, 100 feet of Jindal MLC Pipes will expand 0.713 cm for every 10 deg. C. rise in temperature.

Ease of Handling and Installing:

When rolled down the trench, Jindal MLC Pipes stays where it laid. Jindal MLC Pipes can be cut easily with hand held pipe cutters. And it requires no special bonding procedure. As with any pipe material, normal precaution such as removal of large rocks from around the pipe is advisable.

High UV Resistance:

Unlike the GI and PVC Pipes Composite pipes do not have any effect of UV radiation as carbon black is used. With the use of carbon black, PE pipes as well as composite pipes can be safely used for external installations.

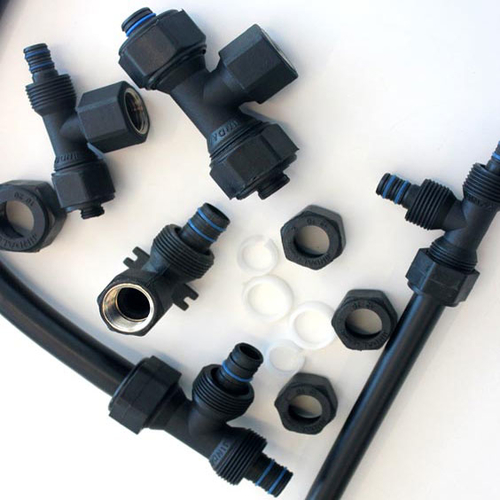

Nature of Joints:

GI pipes are always used with threaded joints. These joints may lead to failure over the time period because of corrosion. Failure of joint due to faulty jointing can also not be ruled out.Copper pipes are safer in case of solder joint can not be done at the place of installation, particularly incase of concealed piping. Hence, the piping has to be completed outside and then fitted in the wall. In such cases, addition of a fitting or maintenance of piping becomes very difficult. Threaded PVC pipes carry the same disadvantages as GI pipes.

Composite pipes are generally jointed by compression fittings. Ease in achieving closer manufacturing tolerance facilitates the use of compression fittings. These joints are very easy, fast as well as safe against leakages.

Good Flexibility:

GI and PVC pipes are rigid and hence can not be bent. Copper pipes can be bent with mechanical tools. The time required for bending is comparatively high. Composite pipes can be safely bent by hand when used with a protective support springs to a radius of 5 times the outer diameter of the pipe. After bending no spring back is observed so there is no need of clamping.

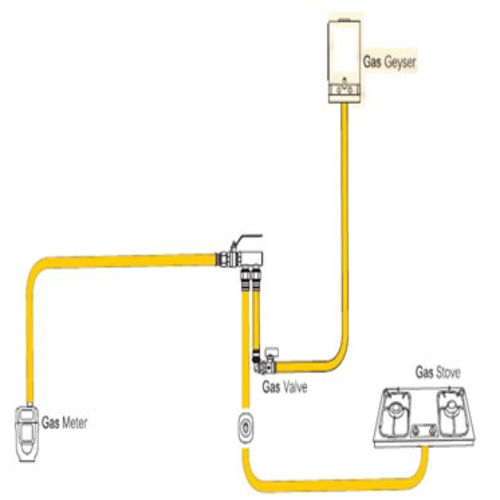

Demanded for:

Cold & hot water Plumbing & distribution

Under floor heating System

Solar Water Heating System

Jet pump piping, subermisible pump piping

Pneumatics, compressed air in textile, automotive industry.

Medical, Foodstuff & Chemical Industry's Pipe System

LPG & Natural gas distribution Vacuum Systems

Insecticides spraying

Radiator Central heating

Cable conduits

Diesel, petrol & Petroleum products

Central air conditioning and blower

Refrigerant systems

Data transmission and Telecom

Pricing Details

Pricing Details

Product Specifications

Product Specifications

Content library

Content library

Know more about us

Know more about us

Pricing Details

Pricing Details

Our wide range of products and services

Our wide range of products and services