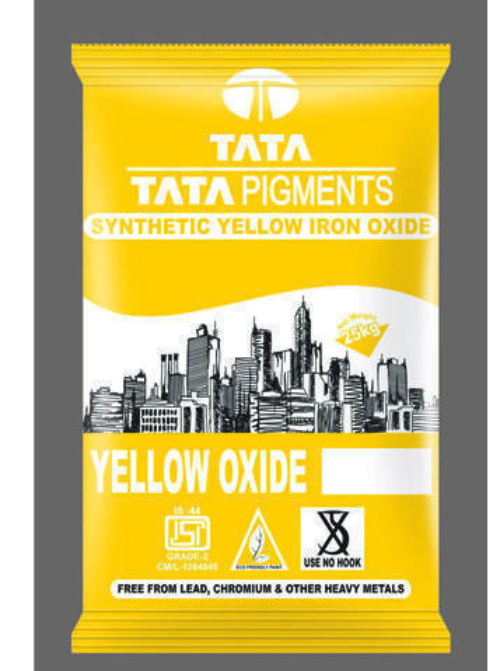

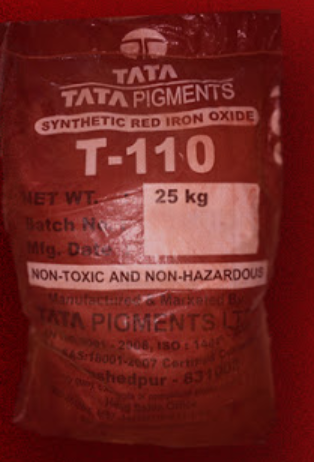

Product Description

Orange oxide is a highly concentrated dry powder of the finest grade and is ideally suited for use in paints, rubber, paper, polishing rouge, ceramic, linoleum, wall paper, plastic asphalt,

cement colours, mosaic tiles and flooring. It is also plays a role in foundry core making and ferrite, which is used by the electronic industries.

Other Details:

- Conforms to Bureau of Indian Standard Specification No. IS 44-1991

- Free From Lead, Chromium And Other Heavy Metals

Salient Features:

- Tata Orange is ideally suited for flooring and they have the best mobility with cement.

- Resistance to alkali and light fastness are excellent

- Tata Orange furnishes the floor with a bright, shiny and smooth surface.

- Tata Orange is non toxic and non inflammable

- Tata Orange has permanent colour stability and resists fading.

Uses:

- Tata Orange is highly apt for colouring of cement and mosaic floors, tiles, dadoes and plastic works colour wash.

Application Procedure:

Complete and careful mixing of the Tata Orange colours and cement is imperative for best results. Tata Orange should be mixed with grey or white cement in the proportion 1:3 or 1:4 (colour of cement), depending upon the desired depth of the colour- [Grey cement is recommended for deep shades and white cement for pastel shades].

Moreover, to eliminate the occurrence of patches and also to produce a smooth and uniform finish, the colorant and cement must be mixed in a dry state before adding water. The mixture has to be applied by trowelling. A 24- hour gap has to be maintained before curing is undertaken for setting.

Precaution:

For better results, it is necessary to prepare a homogenous mixture of Tata Orange and Cement in a dry state before adding water.

The chore of mixing and application must be done by an experienced mason.

The dry mixture should be prepared just before applying it.

The wet floor surface must be protected from dust, direct sun light and damage of any other nature.

Use of chalk powder with the dry mixture of colours and cement must be avoided as it dilutes the intensity of the

colour

Any contact between Tata Orange and acids or acidic materials must be prevented.

Tata Orange may be used for interior and exterior applications.

Polishing:

- Buffing and polishing should be undertaken after the floor has been allowed to dry for a week. More time will ensure better setting.

Covering Capacity:

1 kg of Tata Orange, when mixed with cement in the ratio of 1:5 and applied so as to have a floor thickness of 1 mm, will cover the below mentioned floor area:

Tata Orange 60 square feet

Packing:

- Packed in 25 kg laminated HDPE bags and 1 kg and ½ kg HMHDPE pouch with line

Pricing Details

Pricing Details

Product Specifications

Product Specifications

Content library

Content library

Know more about us

Know more about us

Pricing Details

Pricing Details

Our wide range of products and services

Our wide range of products and services